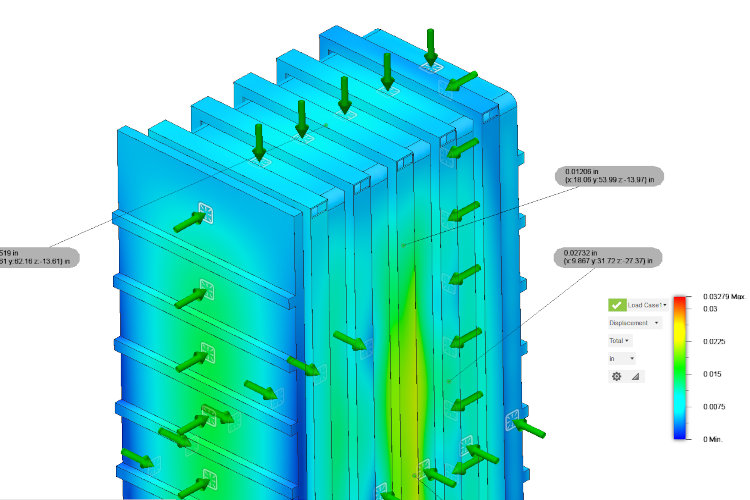

Quality Control & Customer Focus

E-Sector prioritizes the Quality of our work and the Satisfaction of our Customers.

By promoting a culture of Quality Control and awareness training, we ensure all team members, from our skilled technicians to our Senior Management, understand their role in overall Customer Satisfaction and delivering a Quality product on-time.

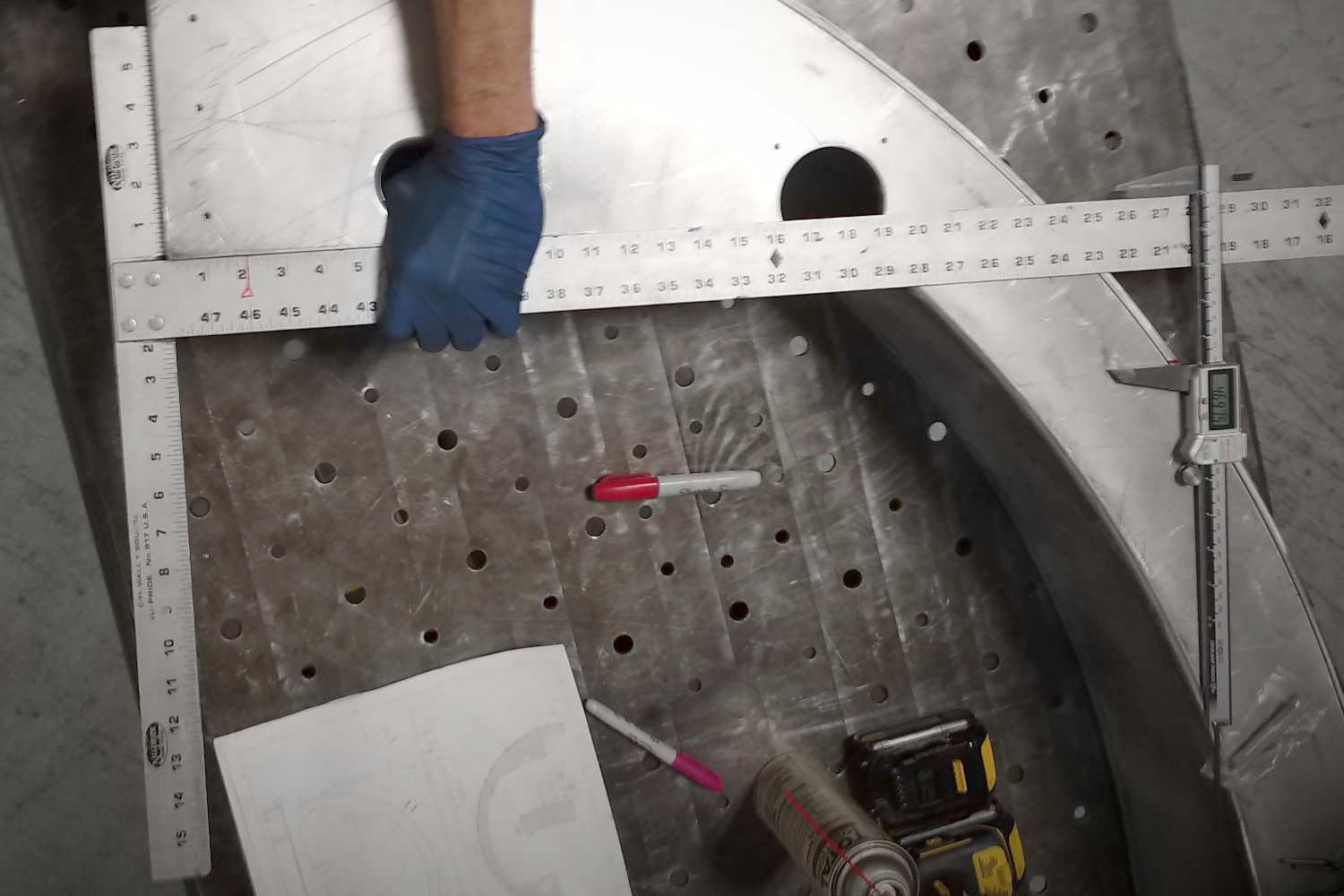

Non-Destructive Testing

E-Sector can perform various NDT services on-site for your critical applications. Hardness testing, Pressure Test, Vacuum Test, Visible Dye Penetrant & Fluorescent Dye Penetrant Testing per ASNT SNT-TC-1A.

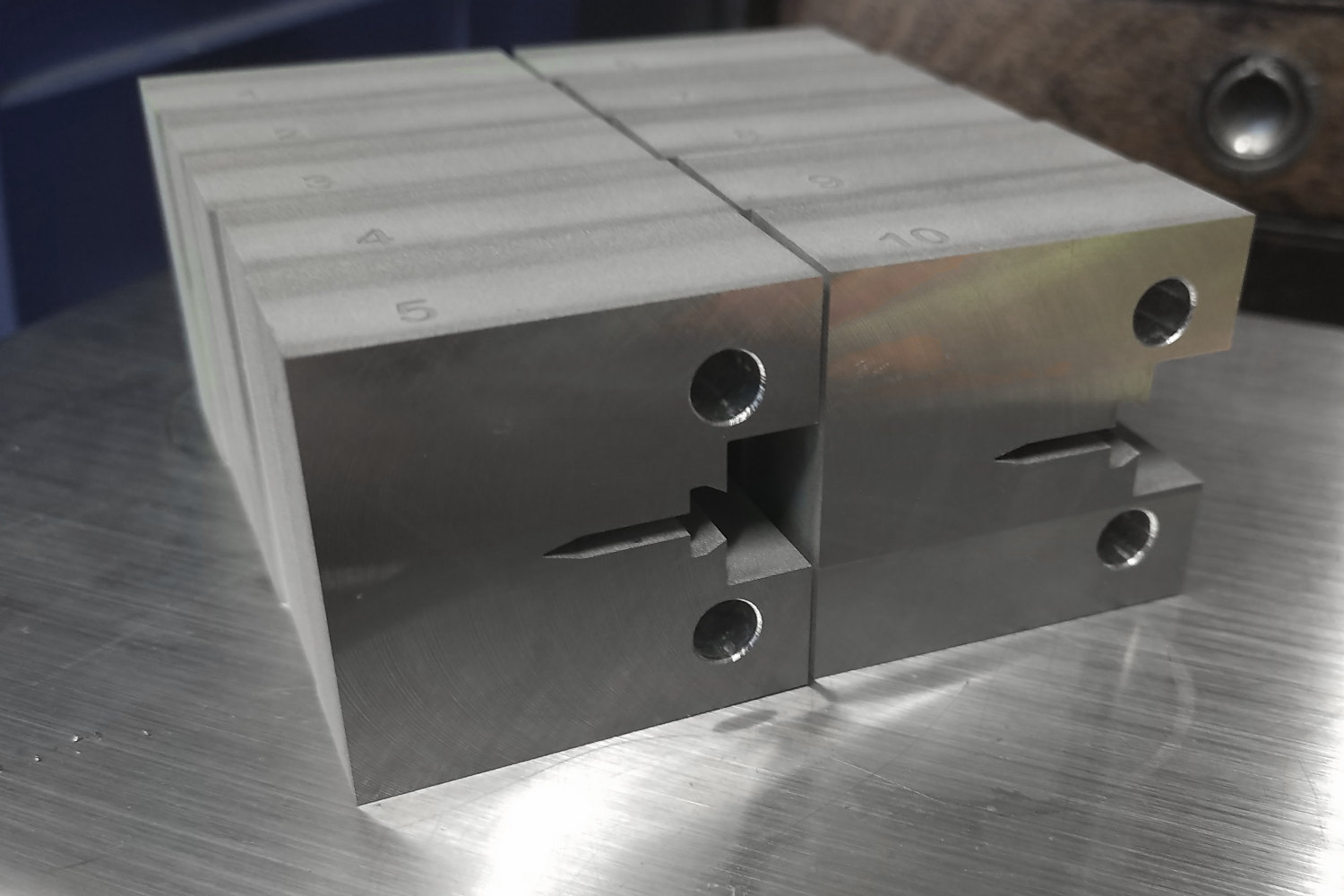

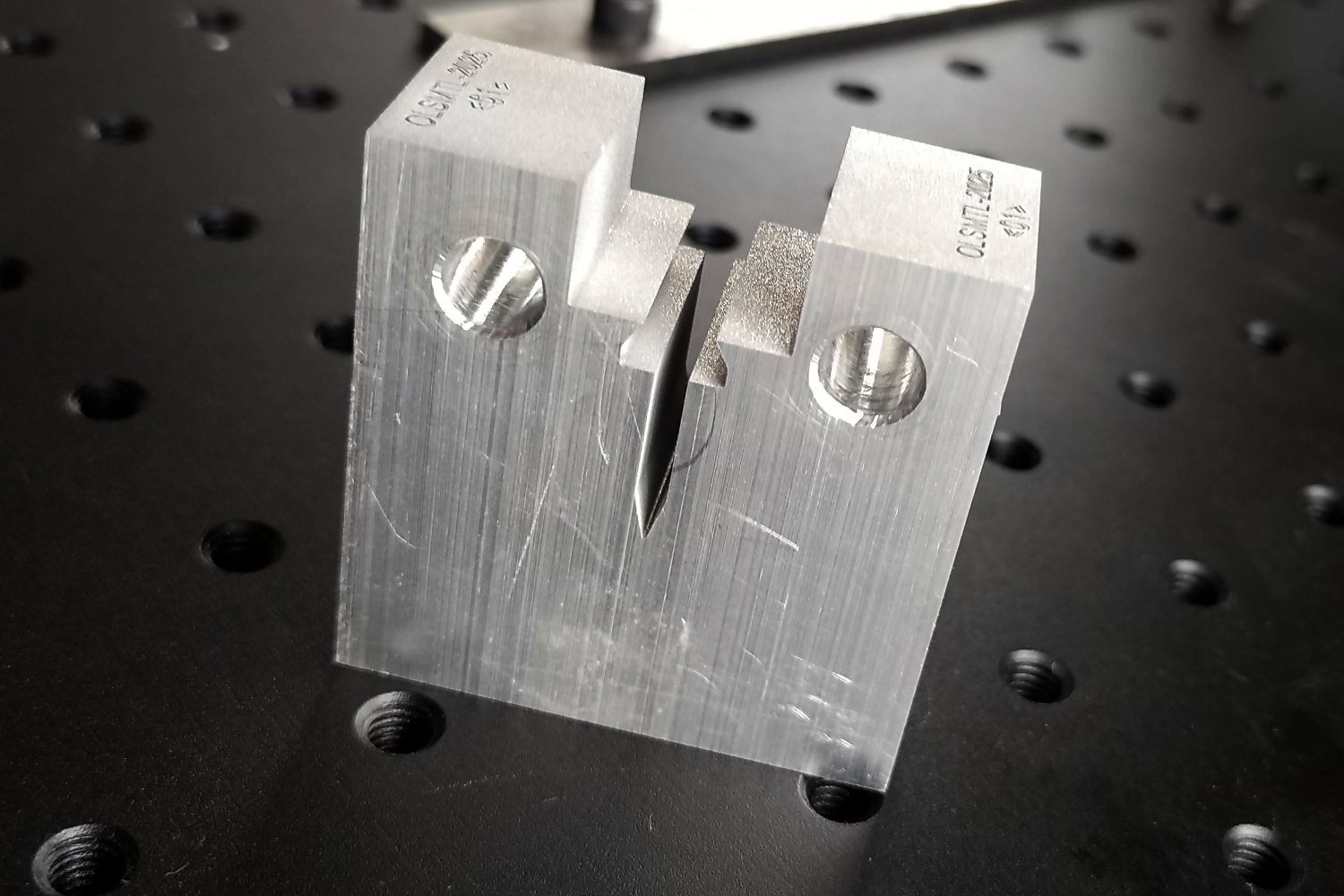

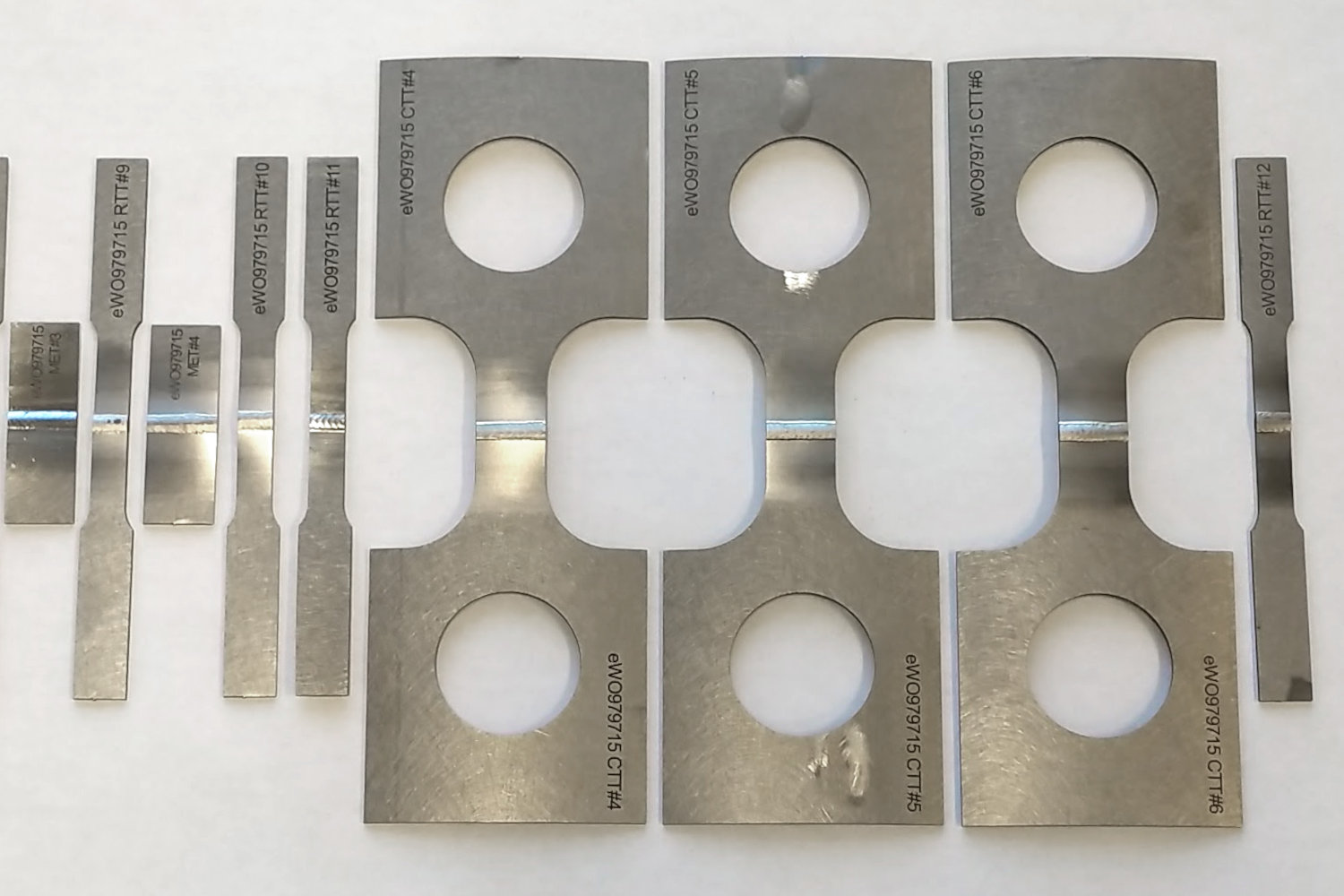

Destructive Testing

We also have specialized equipment for destructive testing and metallurgical sectioning.

Our Waterjet can slice through any material (Metallic or Non-metallic), which supports destructive testing of large or odd shaped pieces like Blades or Airfoils.

Our EDM (Electrical Discharge Machining) Wire can slice thru any metallic alloy up to 6” thick with precision. If you need metal sectioning, weld sectioning, tensile bars or strips, coating specimens, or any other metallurgical evaluation, we can accelerate your analysis by providing fast and accurate cuts to support your lab evaluation and destructive testing needs.

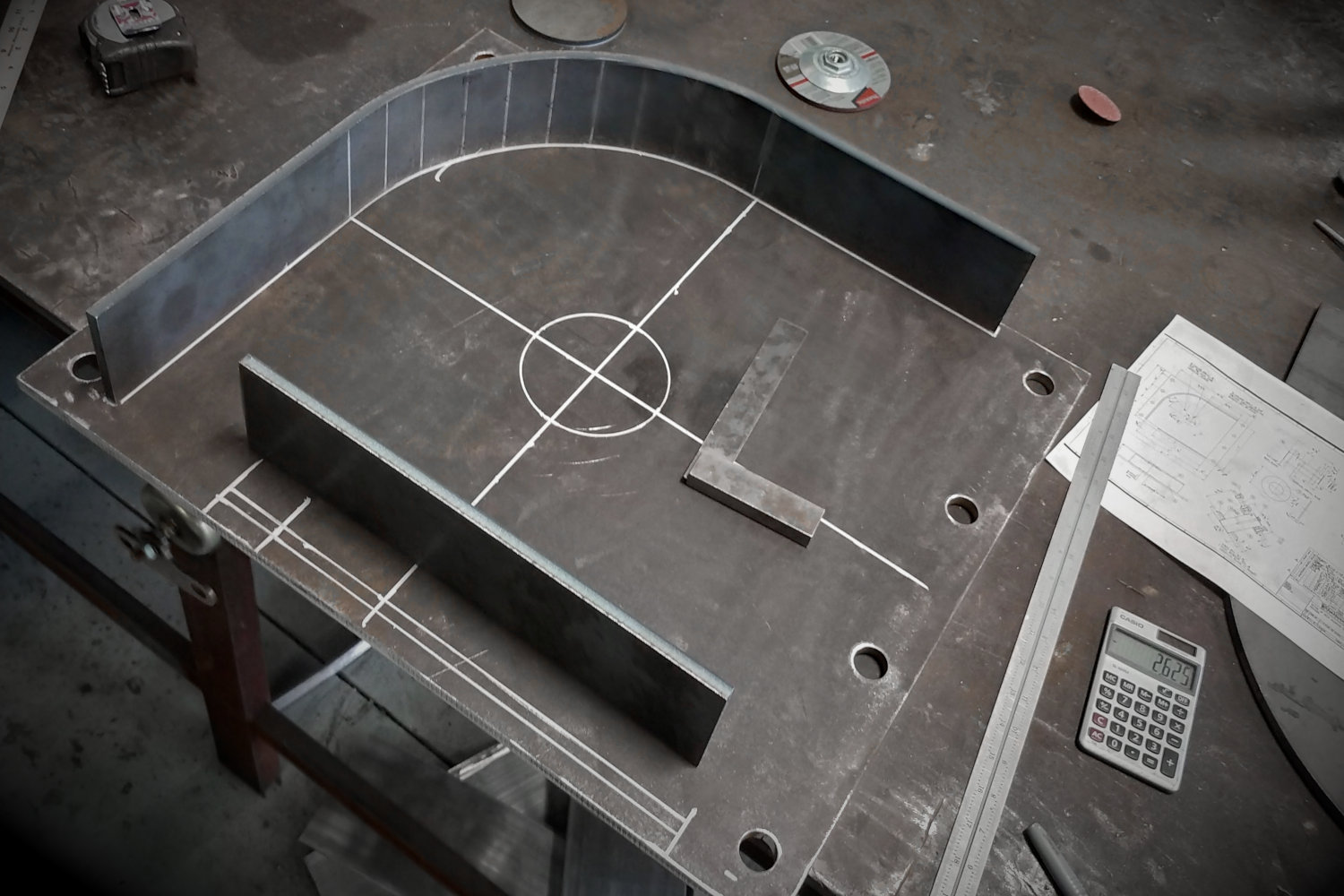

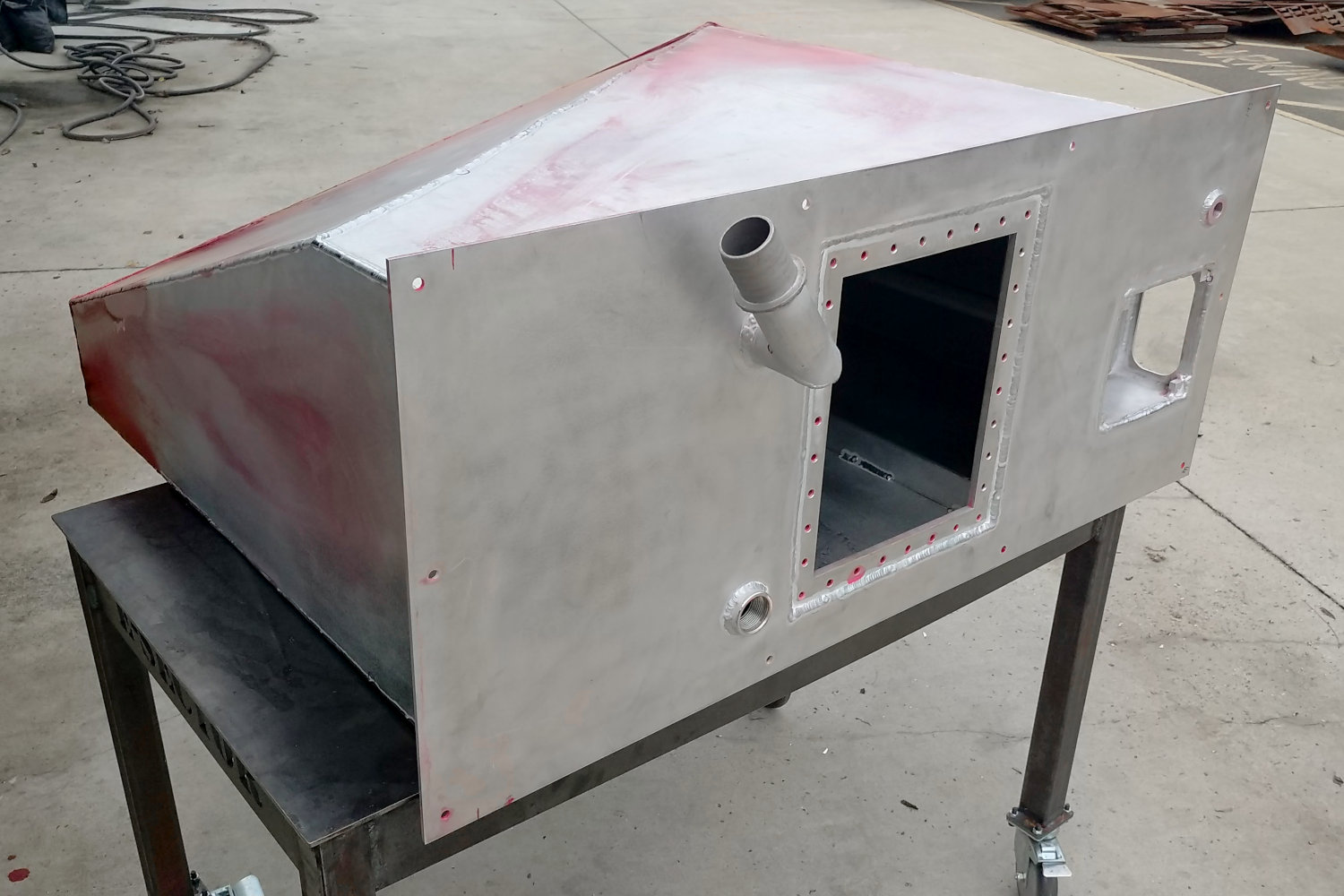

Professionally Certified

E-Sector offers Certified welding per AWS D1.1, D1.4, and D1.6, among others. All welding personnel and processes are certified by a 3rd party Testing Service which is accredited and licensed by the American Welding Society (AWS) as Certified Welding Inspectors (CWI’s). E-sector is qualified to perform TIG and MIG welding for Steel, Stainless Steel, and Aluminum alloys.

E-Sector’s Key processes are certified to ISO 9001:2015 Quality Management System. Our Quality is maintained via internal and external Audits, Root Cause/Correction Actions, and other Continual Improvement methods and tools.